- #Laserdrw software how to

- #Laserdrw software install

- #Laserdrw software driver

- #Laserdrw software pro

They will teach you what to look for in an image and how to best process them for a variety of substrates. Look through the courses and see what you think. There is a site with inexpensive (and free) tutorials that mostly cover epilog and CorelDRAW but the image manipulation tools (brightness, unsharp masking, resolution, contrast, etc…) are the same, or similar, across most of the raster (and many vector) design applications. Learning what setting do what and how it affects the outcome is a valuable lesson that can be implemented from here on out. Below is a good epilog article on installing and using the wood photo engraving macro in CorelDRAW and I’m sure there are others: Īdditionally, you could use Photograv, a similar image preparation software, or other services but they can be very expensive, don’t always do a perfect job, and you don’t really know what it’s doing. So essentially anything that can be printed or plotted can be sent to the laser. There are also a number of macros and plug-ins to help automate (or at least streamline) the workflow.

#Laserdrw software driver

If using the ULS color palette be sure to default your color space to RGB (and not CMYK) and use the same identical color palette that your laser driver uses because most laser control software uses the RGB color space but I did confirm that LightBurn software can use RGB and/or CMYK modes. FlexiSign even had a ULS color palette available that you just import and use.

These programs like Inkscape, CorelDRAW, illustrator, etc… Can have custom color palettes (or, in some cases, import predefined color pallets specific to the laser driver) so your layers are already formatted correctly. Many vector based design software use colors to designate layers and the epilog driver interprets the correct colors as to the process that will be performed on that layer.

#Laserdrw software pro

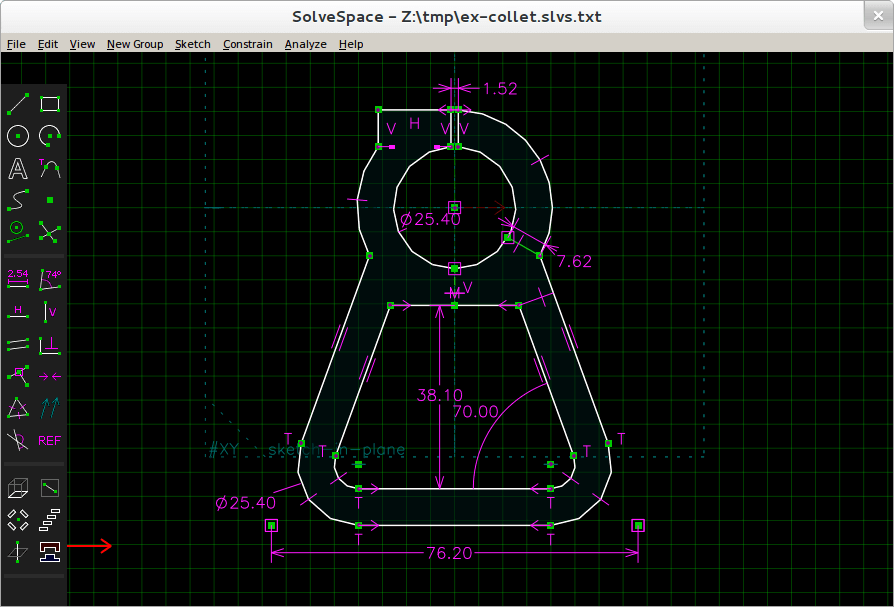

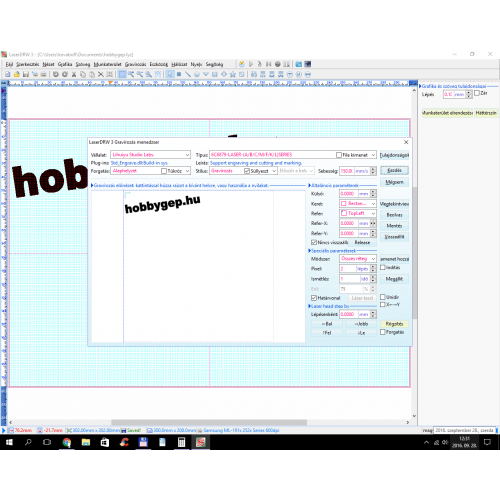

I have used everything from notepad to FlexiSign Pro and with the right settings it works great. The typical workflow is to design in the design software you prefer, export the file in a format that your laser control software will accept, and import the file into your control software to send the job to the laser. More On Control Softwareĭesign Software is natively not designed to control your laser and is independent of the laser control software. Some people who use these advanced control applications design in the control app without even using a 3rd party design suite. Some control software has no design or editing function at all and some, like LightBurn, have fairly advanced design functions built in. CLICK HERE FOR HELP IDENTIFYING YOUR CONTROLLER. Close LaserDrw, open Corel Laser (it will start CorelDraw with the plugin icons available on top right) Check the configuration icon (up by the cut and engrave icons) again from CorelDraw to set the correct machine model again.

#Laserdrw software install

Control SoftwareĬontrol Software is specific to certain laser controllers and DSP’s and is primarily used to control the laser. Install LaserDrw Open LaserDrw and make sure the correct machine model is selected in the configuration. This article will touch on many of these applications and their functions. I discovered a myriad of different programs for controlling and design purposes. I have used a variety of US based lasers (ULS, Epilog, etc…) as well as quite a few Chinese lasers with different controllers. The Difference Between Control Software and Design Software 1 The Difference Between Control Software and Design Software.It's driving me mental, and any suggestions would be massively appreciated. I'm producing SVG files and loading them into CorelDraw12 with the supplied laser etching plugin. I've experimented a lot and I can't find a way to specify the path I want the laser to take other than "shortest path" and a few other even more inefficient options. Ideally I think it would be 1000x faster if the head would just travel back and forth row by row and etch where necessary rather than taking these stupid paths. A 95mmx50mm surface about 1/3rd filled is taking 3-4 hours because the laser head moves up, down, and then fires a tiny burst to etch a single line. The path chosen by the laser is absurdly stupid and lasering times are absolutely astronomical. I've gone through the learning process of actually getting things etching and they are turning out really well, except for one major frustration. I bought a cheapo chinese usb 40w laser with CorelLaser/LaserDRW software.

Major newbie here - I'm creating cold storage wallets for bitcoins, laser etched on wood.

0 kommentar(er)

0 kommentar(er)